Created on 2025.04.12

plate cutting machine CNC30

1. Technical data of the Machine

Length of guided rails: 8000mm

Track width: 3000mm

Effective cutting scope: 6400mm

Cutting width of single torch:2400mm

Cutting speed:50-1000 mm/min ( stepless adjust )

Travel speed: 6000mm/min

Cutting thickness: 6~25mm

(apply in Plasma torch , PMX125 Pierce thickness can to25mm)

Cutting thickness: 25~100mm (when using 1 group of flame torches)

Transverse torch:1 CNC flame and with automatic ignition; 1 CNC plasma and with ARC Voltage THC

Plate cutting machine CNC30 (CNC machine) is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

Longitudinal torch:NO .

Surface quality for cutting:≥Ra12.5

Precision of the Plate cutting machine CNC30: Suitable for JB/T 5102-1999

Air proofing of the whole machine: Suitable JB/T 5101

Precision of cutting position: ±0.5mm/1000mm

CNC controller: 1 set, CCM3

Cutting gas: Oxygen

Cutting material: Q235-A mild steel

Working condition: inside temperature 0-45℃, relativity humidity ≤90%

Input power: 1PH AC240V/3PH AC380V 50Hz ( user specify)

2. Summarize:

The machine is mainly used for shape/strip flame cutting on metal-plate, with advantages of complete functions, high automation, advanced configuration, accurate cutting, good quality and stable movement. CNC、servo-system are all international renowned ones. High quality product and friendly operating-interface guarantee ideal cutting equipment for users.

( only refer)

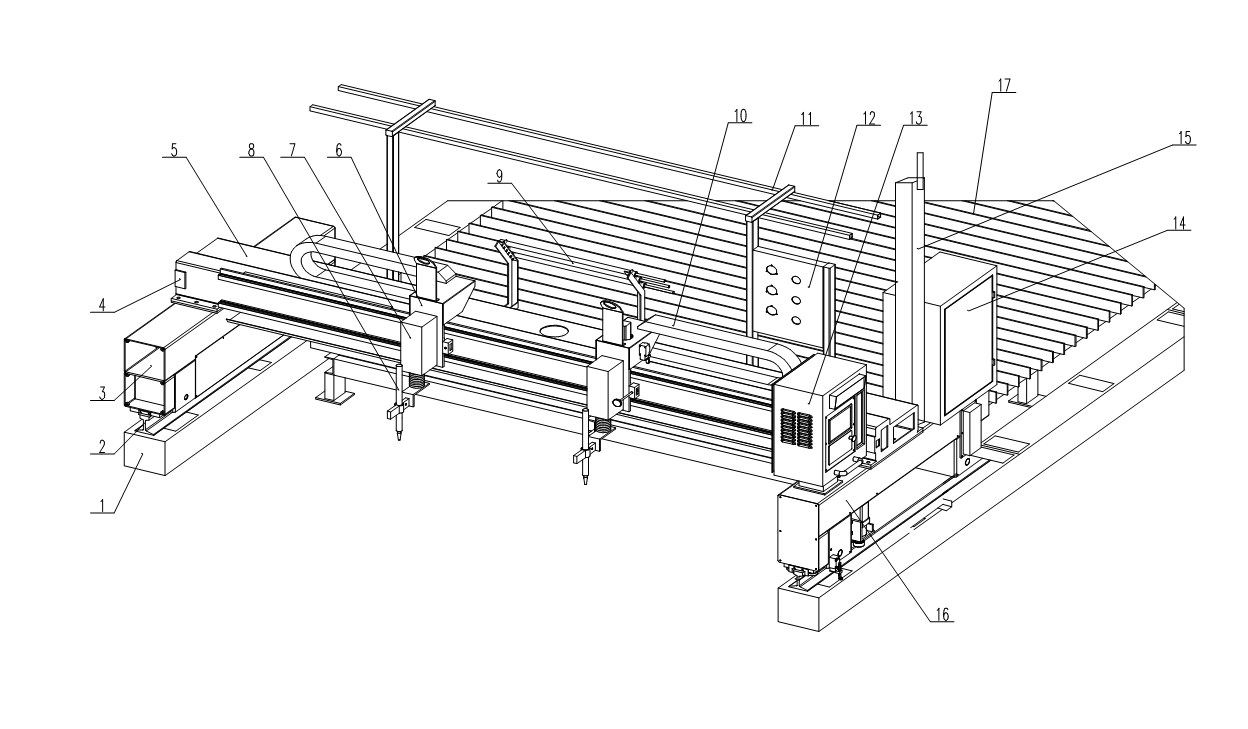

Figure sketch of CNC/multi-head flame cutting machine

1-support beam (prepare making by client); 2-longitudinal rail and its accessories; 3-main idle boom; 4-steel-band transmission unit; 5-main beam; 6-torch carriage ; 7-lifter ; 8-CNC flame single cutting torch; 9-Rack of cable and gas hose for strip torch; 10- transverse drag-chain; 11-support rack ( not including when no Longitudinal torch ); 12-gas source control panel; 13-CNC operating box;14-main box ; 15-Rack of longitudinal cable-slides(prepare making by client) ; 16-main power boom; 17-cutting table (prepare making by client)

Remarks: The sketch is for reference, detail position of elements need to adjust according to real condition.

3. Performance and characteristic

The machine is mainly used for shape/strip flame cutting on metal-plate, with advantages of complete functions, high automation, advanced configuration, accurate cutting, good quality and stable movement. CNC、servo-system are all international renowned ones. High quality product and friendly operating-interface guarantee ideal cutting equipment for users.

Basic configuration:

Rail span:3000mm

Length of the guide-way: 8000mm

CNC system: 1 set, CNC-M3

Driving system: 1 sets, high-precision AC Panasonic Drive motors

Longitudinal and transverse reducer: 2 sets, ,

CNC flame single cutting torch:1 groups

Drag chain of CNC cutting torch: 1pieces,

Strip single cutting torch: NO

Gas supply: Centralized gas-supply

Way of setting: transverse carriage and cables, trolley of longitudinal cables

Cutting gas: Oxygen, acetylene (for other kind of gas please specify)

Main electric components: Schneider

CNC system:

CCM3 CNC is the most versatile CNC offering from Beijing Flourishing Start Digital INC , it control package provides a unique combination of configurations, expandable features, and common software . this scalable CNC offers the OEM the ability to standardize on their hardware solution without compromising application range; it has 10” color display screen and intergrated keyboard panel ; it adopts industrial ARM chip, superlarge scale intergrated high speed hardware interpolator ,low consumption, low heat , no forced cooling, stable and reliable hardware; Software feature-rich, free flame cutting, plasma two type conversion, can adjust the preheating time delay characteristic according to cutting material and machine, punch cutting torch lift time delay, the perforation parameters such as delay. Software has plate straightening, slotting compensation, breakpoint recovery, the original track back processing and transfer of cutting, choice of arbitrary point start the procedures section, perforation and cutting any position adjustment and choice, preliminary outline, part rotation, mirror, array, scaling and processing a variety of ways. Software has Chinese/English two kinds of operation interface, dynamic graphical display. Dynamic trajectory simulation processing, real-time display of cutting state and input/output state. Software is equipped with standard atlas, the convenient user use, also can use the built-in or external keyboard manual programming.

10.4” DISPLAY Memory: 64-512 Megabytes RAM

Supportable axes : Standard 2; optional expansion up to 4 axes |

USB port: 1 x USB port accessible from the front panel allows

use of memory sticks and other devices.

Input / output: 40 Lines of user definable interface signal (20 in / 20 out)

Operating environment: 0 to 50°C; 95% relative humidity (non-condensing);

on-board voltage and temperature monitoring

* Information subject to change without notice under Beijing Flourishing Start Digital INC. |

Driving system:

1) Display of states, diagnosis、alarm and parameter setting

2) Manual or automatic set rigidity of driving system, fully ensuring machining stability

3) Motor revolution、command pulse、effective load ratio can be adjusted, also various kinds of alarm and malfunction can be diagnosed

4) The motor material is high magnetic thulium, with advantages of magnetic conductivity and radiation, high density of magnetic flux, little change in dynamic characteristic

5) Through precise detection by pulse encoder of servomotor, the speed and precision of servomotor can be fully ensured.

Beam of main frame

The main frame is of Π-shape box structure,compact in structure and pretty in appearance,and stress relieved after welding. One side of driving frame is fit with horizontal control roller, which can adjust its pressing degree against rail, making stable running of entire machine during working. There are scrapers at both sides of driving beam for scraping sundries amassed on the surface of rail all the while. The beam is bent and welded into shape with quality steel,and stress-relieved through tempering integrally,then gone through finishing mechanical processing,with good rigidity、shock-absorbing performance、high intensity and little inertia. Precise linear ball bearing guide-way and precise rack are assembled on it, ensuring transverse precision. Transverse rack is fixed with bolt onto beam,ease of replacement and adjustment in time.

Transmission type: gear and rack

It makes servo motor, precision gear reduction and gear & rack become transmission chain without intermission, which ensure transmission precision and make the complete machine have excellent functions of buffering and accelerating.

Lifter

Torch elevation control unit is consists of motor, driven through high precision reducer、precise lead-screw. There are electrical limit switches along valid stroke of torch, with dust-proof cover outside. It has advantages of reasonable structure, flexible and reliable elevation, high-precision positioning. It is elevated with motor.

Pneumatic system

The system is controlled centrally, including pressure valve、pressure gauge、gas tube and corresponding accessories. With imported high-intensity pressure-proof gas tube and flashback arrester, the safety and reliability of gas supply can fully be ensured.

4.0.4. Range of supply and components

●Main frame: including beam、longitudinal driving side-beam、longitudinal and

transverse gearbox ()、steel-band transmission unit、gear、rack、control board、

CNC box、1 sets of CNC flame single torch、operating table, transverse drag-chain、cables;

●Longitudinal rail (24Kg): including 8m×2 rail. For rail fixation we can offer

工-beam or concrete drawing according to customer requirement;

● Electric system: 1set, including CNC、driving system、air breakers、A.C.

Contactors、intermediate relays、D. C. Power supply、limit switches、cable and

plugs、controlling panel, pushbuttons;

● Pneumatic system: 1 set, including general solenoid valve、torch solenoid

valve、gas panel、pressure adjustment valve, pressure gauge、oxygen-pipe array、

cutting-gas array、oxygen pipe、cutting-gas pipe and cocks;

● Information materials:including 1 copy manual book,1 copy of Panasonic servo driver manual book,