Created on 2025.04.12

MANIPULATOR WM4040 (sets)

MANIPULATOR WM4040 (sets)

1.Summarize:

● Column-boom WM4040 (movable and revolve) 1 set

● KB-10 Seam Tracker (optional) 1 set

● DC-1000 welding system (optional) 1 set

● Flux send and recovery system 1 set

● SAR20 welding rotator 1 set (1P+1I)

2.Technical data

Column-boom:

Structure: movable and revolve

Applicable vessel D: Φ630~4000 mm

Boom travel stroke: 4000 mm

Boom travel speed: 100-2000 mm/min (inverter)

Boom elevation stroke:4000 mm

Boom elevation speed: 1050 mm/min

Column motor-driven revolve angle: ±180°

Column manual revolve speed: manual

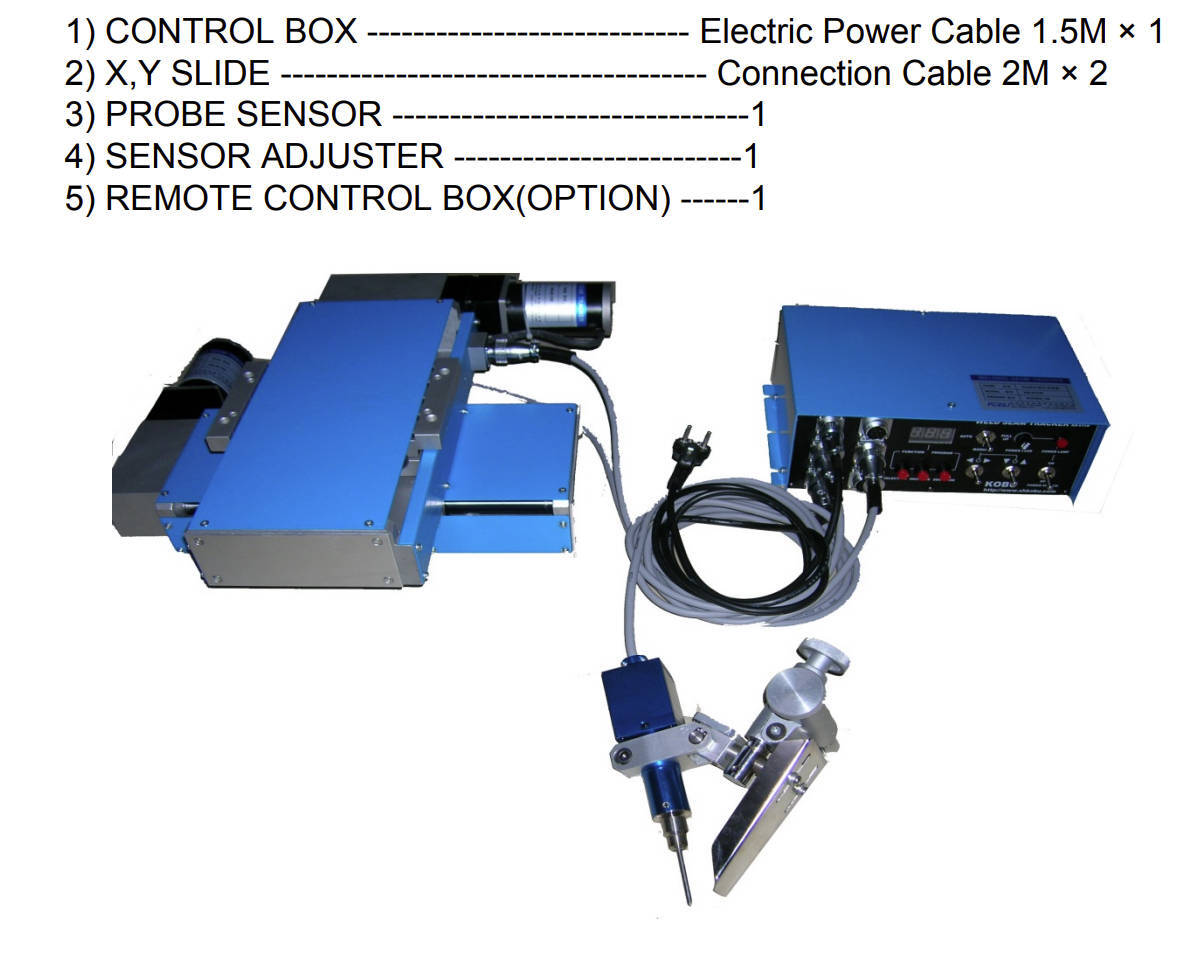

Seam-tracker:

Model: KB-10

Testing range: 100 mm

Testing speed: 200 mm/min

Testing precision: ±0.3 mm

Loading: 100 kg

Power: AC220V

DC1000 SAW power with control box and wire feeder.

(CHINA AOTAI)

Rated welding current: 1000A

Idle voltage: 75V

Duty cycle:100%

Current range: 200~1000A

Wire D: 3~6 mm

Welding speed: 15~75 m/h

Flux feeding and recovery system:FRU80

Recovery distance: ≤16m

Recovery speed: 12kg/min

MANIPULATOR WM4040 (sets) (manipulator) is used in petrochemical machinery, engineering machinery, wind power equipment, construction & bridge, shipbuilding, food & pharmaceutical and other industries

Welding rotator

#1. Max load capacity :20t

#2. Apply in range:Φ500-3500mm

#3. Steel all roller: Φ350*120mm

#4. Power of motor 1.5kw

#5. Speed range adjustable 0.1 to 1 m.min

#6. Moving motor 0.75kw

3. Structure characteristics

This welding center mainly consists of column-boom、SAW and electric system.

3.1 Column-boom

(1)This column-boom is mainly composed of:boom-elevate unit、boom travel unit、column revolve unit、movable trolley、cross-slides、column、boom、trolley、worktable and electric system;

(2) Both column and boom are rectangular-section beams, with double-rail, which is welded into shape、stress-relieved and mechanical machined finely, ensuring higher

precision;

(3)Boom-elevate unit is installed at column-top, composed of A.C. braking motor、reducer、chain and sprocket. It has counter-balance, making stable boom elevation. To prevent chains from incidental broken, ratchet-type anti-dripping unit on the column is used for safe and reliable operation.

(4) There are 8 sets of control rollers on the saddle along vertical and horizontal movement. Each set has 3 control rollers. These control rollers are contacted with rails of boom and column through 3-sides, of adjustable eccentric structure, with great loading capacity, making good contact between them and rail surface, ensuring smooth and no

shivering boom travel;

(5) Boom travel is realized with A.C. inverter motor through worm-gear reducer

driving gear-rack. Its speed can be adjusted within 100-2000mm/min through inverter,

(6) Column is fit onto trolley through heavy-duty cross-roll bearing. Column can be revolved within ±180° manual

3.2 KB-10 seam-tracker

This welding center is equipped with Korean COWELD seam-tracker. Automatic cross-slides of seam-tracker has 100kg loading capacity. The 2 Welding guns are mounted on it, arranged in parallel. Cross-slides is riveted with boom by means of a swivel-shaft, revolving around shaft and then fixed. Swivel of cross-slides can meet inner and outer longitudinal and circumferential welding requirement. It is applicable for double-gun SAW.

3.3 Welding system

American Lincoln DC-1000 welding cable、NA-3S controller and K209A wire-feeder. Wire-feeder is fit on the rack of wire-feeder at the front end of boom. Wire from it is sent to welding gun by way of wire-feeding tube.

3.4 Flux feeding and recovery system

It is adopted with FRU80 detachable flux recovery system. This system can recover residual flux generated during welding process back to its collecting barrel. Flux hopper is fit at front end of boom, flux added by hand.

3.5 Welding rotator

The machine consists of 1 set of driving roller, 1 set of idler roller and electric control system.

ü Driving roller frame is consists of 2 drive rollers and 1 pedestal. The Idler roller frame is consists of 2 idler roller and 1 pedestal.

ü Pedestals of driving、idler rollers are all frame-type welding-members, with great driving force and long life. There are hoisting-holes on the pedestal. Meanwhile, mounting-holes on the pedestal are machined finely post welding, ensuring mounting precision;

ü The rollers are equipped on the support bracket, can AUTO adjust the angle between the rollers group to suit the difference diameter of work-piece, ensuring surrounding angle of work – piece between 45º ~ 110º

ü Each roller on driving-frame are driven by one motor and reducer, achieve rotating. Working principle of the roller: Y series motor—single input and double output worm wheel decelerator —make roller rotating, the wheel linear speed 6-60m/min.

ü The gear reducer is made by our company, which have low noise, big torque, smooth running、little bulk and stabilized speed and so on.

ü Control system consists of control board and remote box. With the control speed of large range and lasting torque, control speed smoothly, no torque pulsant.

3.6 Control system

Control system mainly consists of control board and remote panel.

(1) Control board mainly controls ON/OFF of motors, realizing motions and applying necessary protection on motors, as well as control、speed-control and protection of boom travel motor.

(2) There are limit switches for boom elevation、travel and column revolve, protecting equipment;

(3) Applicable voltage of main frame: 380V/50HZ/3P

3.7 Range of supply

l Welding column-boom WM4040 1 set

l Welding power(D1000、control box and wire-feeder) 1 set

l Automatic seam-tracing system 1set

SAR20 1power unit; 1 idler unit 1 set

l Control system 1 set

l Flux send-recovery system 1 set

l Technical material(with manual book、certificate、foundation drawing) 1 copy English